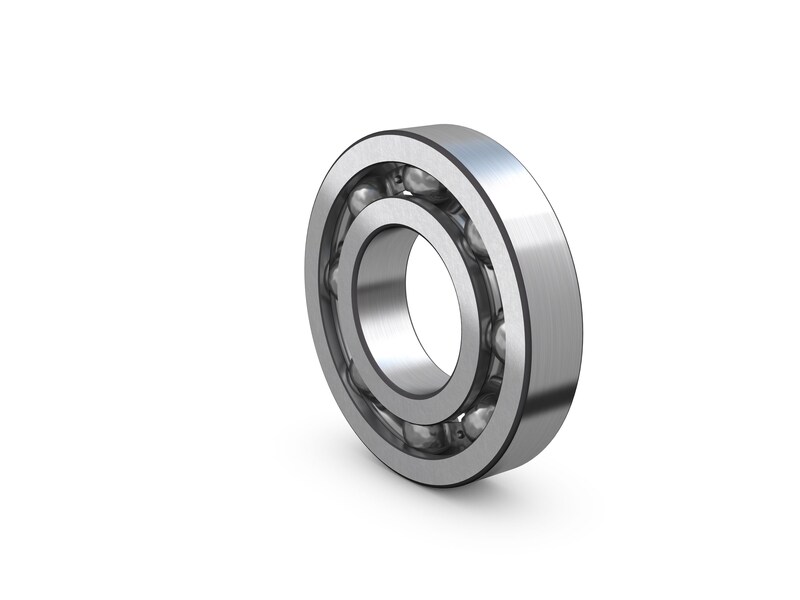

Deep groove ball bearings

.jpg)

Deep groove ball bearings are particularly versatile. They are suitable for high and very high speeds, accommodate radial and axial loads in both directions and require little maintenance. Because deep groove ball bearings are the most widely used bearing type, they are available from SKF in many designs, variants and sizes.

In addition to the bearings presented in this section, deep groove ball bearings for special applications are shown under Engineered products. These bearings include:

- Sensor bearing units

- High temperature bearings and bearing units

- Bearings with Solid Oil

- INSOCOAT bearings

- Hybrid bearings

- NoWear coated bearings

Single row tapered roller bearings

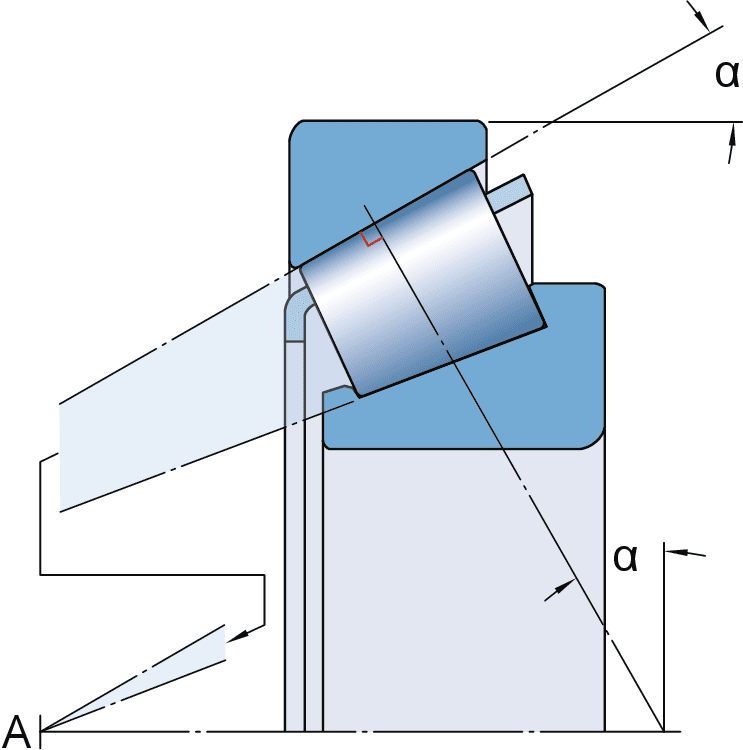

SKF single row tapered roller bearings (fig. 1) are designed to accommodate combined loads, i.e. simultaneously acting radial and axial loads. The projection lines of the raceways meet at a common point on the bearing axis (apex point A, fig. 2) to provide a true rolling action and therefore low frictional moments during operation. The axial load carrying capacity of tapered roller bearings increases with increasing contact angle α. The size of the contact angle, which is usually between 10° and 30°, is related to the calculation factor e (→ product table): the larger the value of e, the larger the contact angle.SKF single row tapered roller bearings are available in many designs and variants (→ Designs and variants) and in many series and sizes, including:

SKF single row tapered roller bearings (fig. 1) are designed to accommodate combined loads, i.e. simultaneously acting radial and axial loads. The projection lines of the raceways meet at a common point on the bearing axis (apex point A, fig. 2) to provide a true rolling action and therefore low frictional moments during operation. The axial load carrying capacity of tapered roller bearings increases with increasing contact angle α. The size of the contact angle, which is usually between 10° and 30°, is related to the calculation factor e (→ product table): the larger the value of e, the larger the contact angle.SKF single row tapered roller bearings are available in many designs and variants (→ Designs and variants) and in many series and sizes, including:- basic design bearings

- SKF Explorer bearings

- application-specific bearings

- bearings with a flanged outer ring

Bearing features

- Low friction

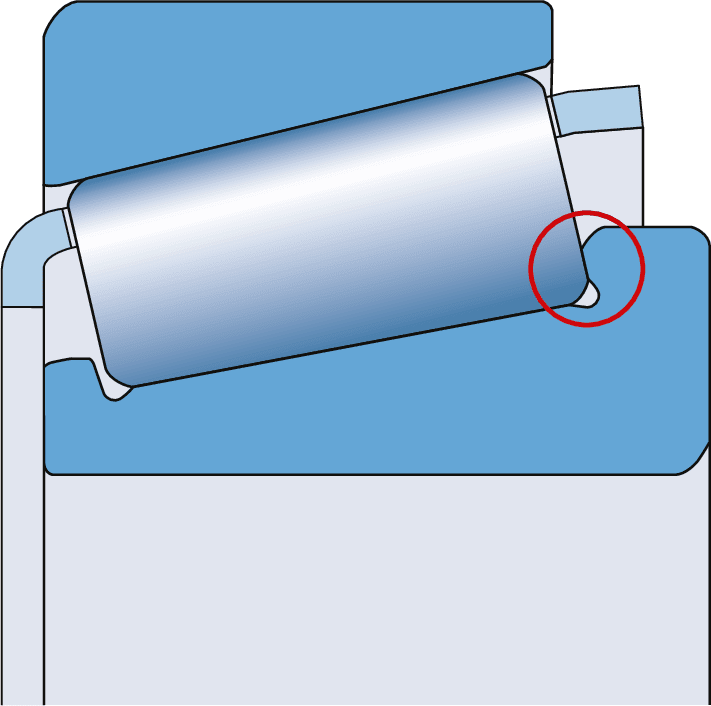

The optimized roller end design and surface finish on the flange (fig. 3) promote lubricant film formation, resulting in lower friction. This also reduces frictional heat and flange wear. In addition, the bearings can better maintain preload and run at reduced noise levels. - Long service life

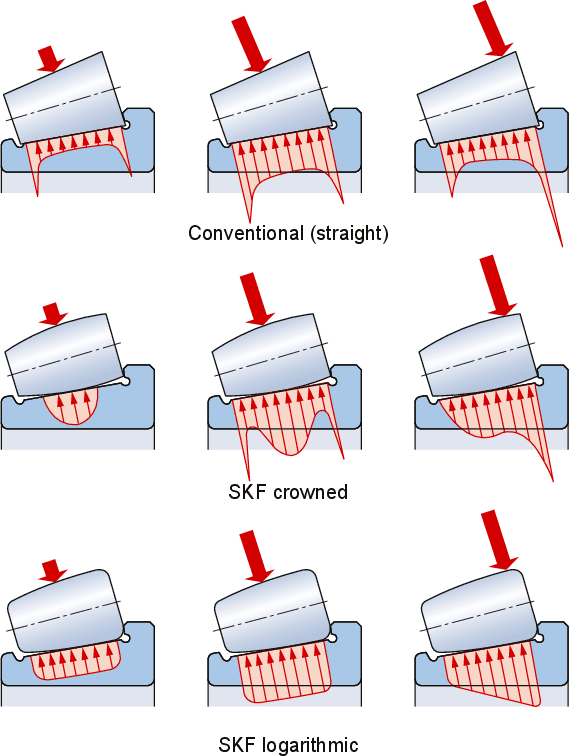

The crowned raceway profiles of basic design bearings and the logarithmic raceway profiles of SKF Explorer bearings optimize the load distribution along the contact surfaces, reduce stress peaks at the roller ends (fig. 4), and reduce the sensitivity to misalignment and shaft deflection compared with conventional straight raceway profiles (fig. 5). - Enhanced operational reliability

Optimized surface finish on the contact surfaces of the rollers and raceways supports the formation of a hydrodynamic lubricant film. - Consistency of roller profiles and sizes

The rollers incorporated in SKF tapered roller bearings are manufactured to such close dimensional and geometrical tolerances that they are practically identical. This provides optimal load distribution, reduces noise and vibration, and enables preload to be set more accurately. - Rigid bearing application

A single row tapered roller bearing is typically adjusted against a second tapered roller bearing. By applying a preload, a rigid bearing application can be achieved. - Running-in period with reduced temperature peaks

Tapered roller bearings typically have a running-in period, during which a conventional design tapered roller bearing experiences a significant amount of friction, resulting in wear. This effect is noticed as a temperature spike (diagram 1). With SKF tapered roller bearing designs, friction, frictional heat and wear are significantly reduced, provided the bearings are mounted and lubricated correctly. - Separable and interchangeable

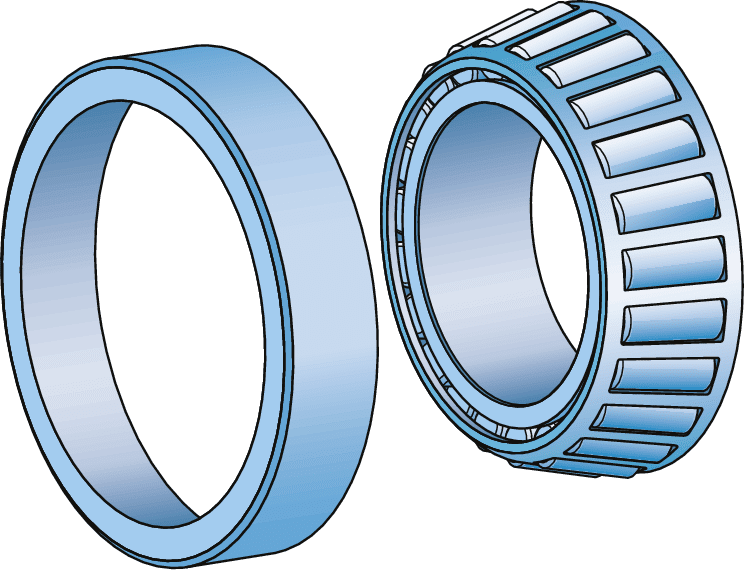

The inner ring with roller and cage assembly (cone) can be mounted separately from the outer ring (cup). Furthermore, the separable components (fig. 6) are interchangeable. This facilitates mounting, dismounting and also maintenance inspection routines.

Comments

Post a Comment